SiDe Design

The Forming of a great idea!

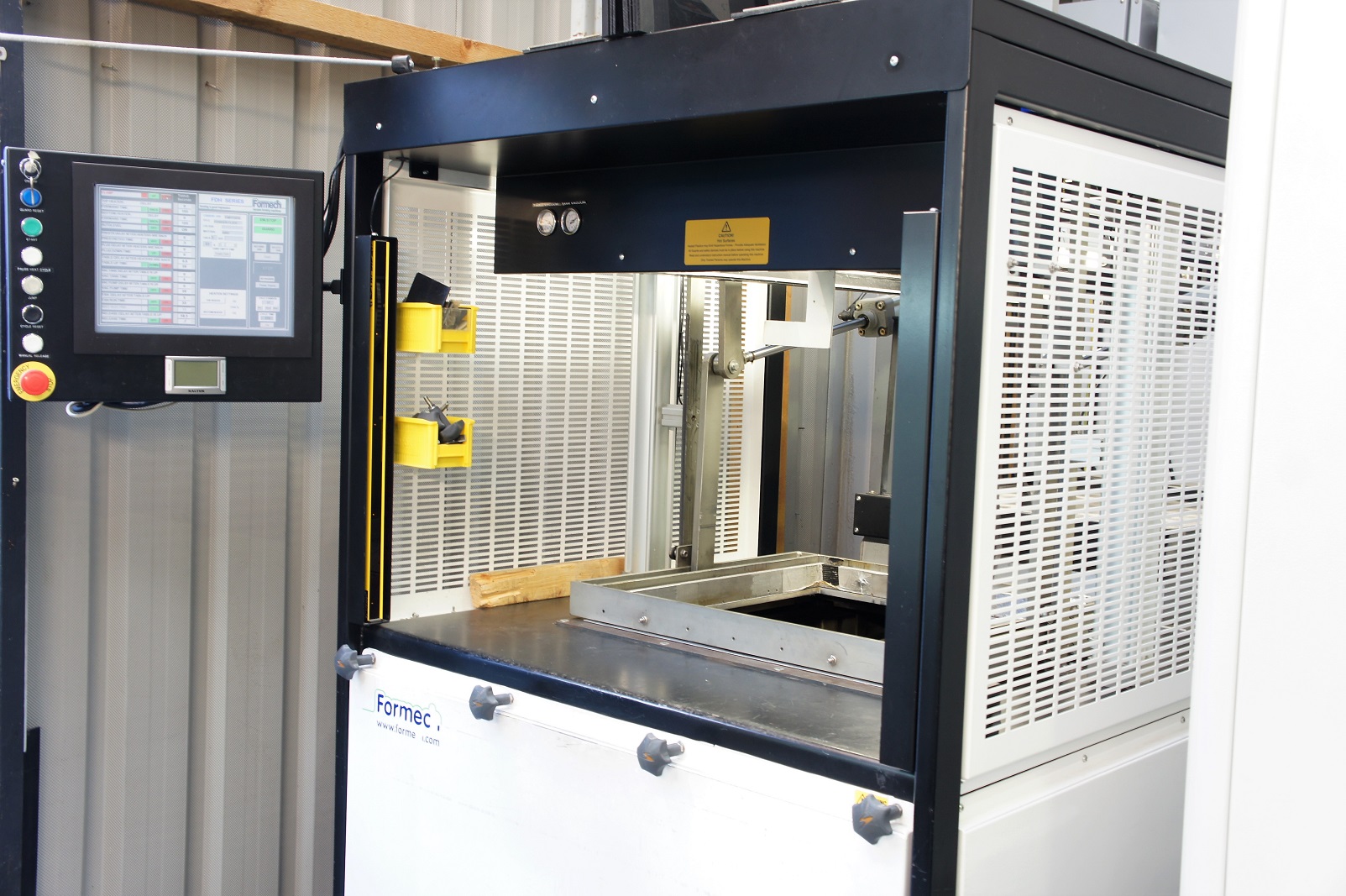

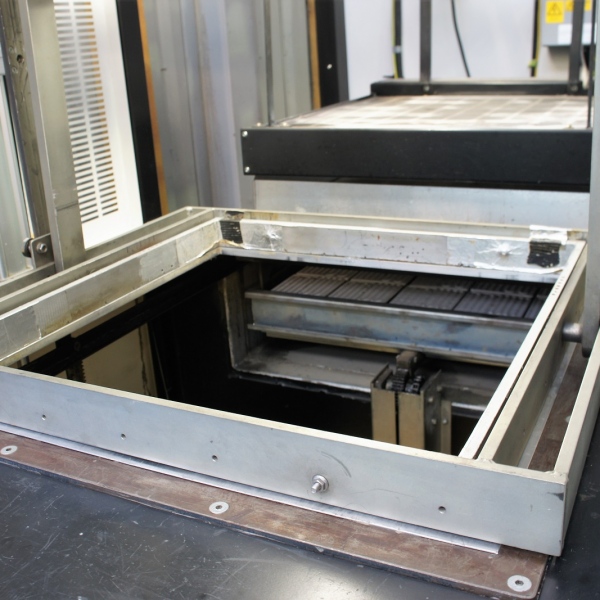

Vacuum Forming, now a very old, tried and tested method of plastics production, still favoured by many with the skills around the world, as “process of choice” for the one off prototype to middle range volume manufacturing. The forming process, in simple terms, takes sheet plastic materials, heating it to a specific point, then on the introduction of a forming tool, creates a vacuum to draw the sheet material around the shape. A main reason for this process to remain extremely popular is that the tooling produced to create prototypes or production are considerably quicker and cheaper in comparison to, let’s say, injection moulding, which tend to require high volumes of production to justify the expenditure. Our in house facilities offer the ability to efficiently create tool designs with high detail, as well the vacuum forming service itself for both testing prototypes, low, medium to high production runs. This can in turn be linked to our 5 axis CNC service for a fully finished component.

SiDe Design

SiDe Design