SiDe Design

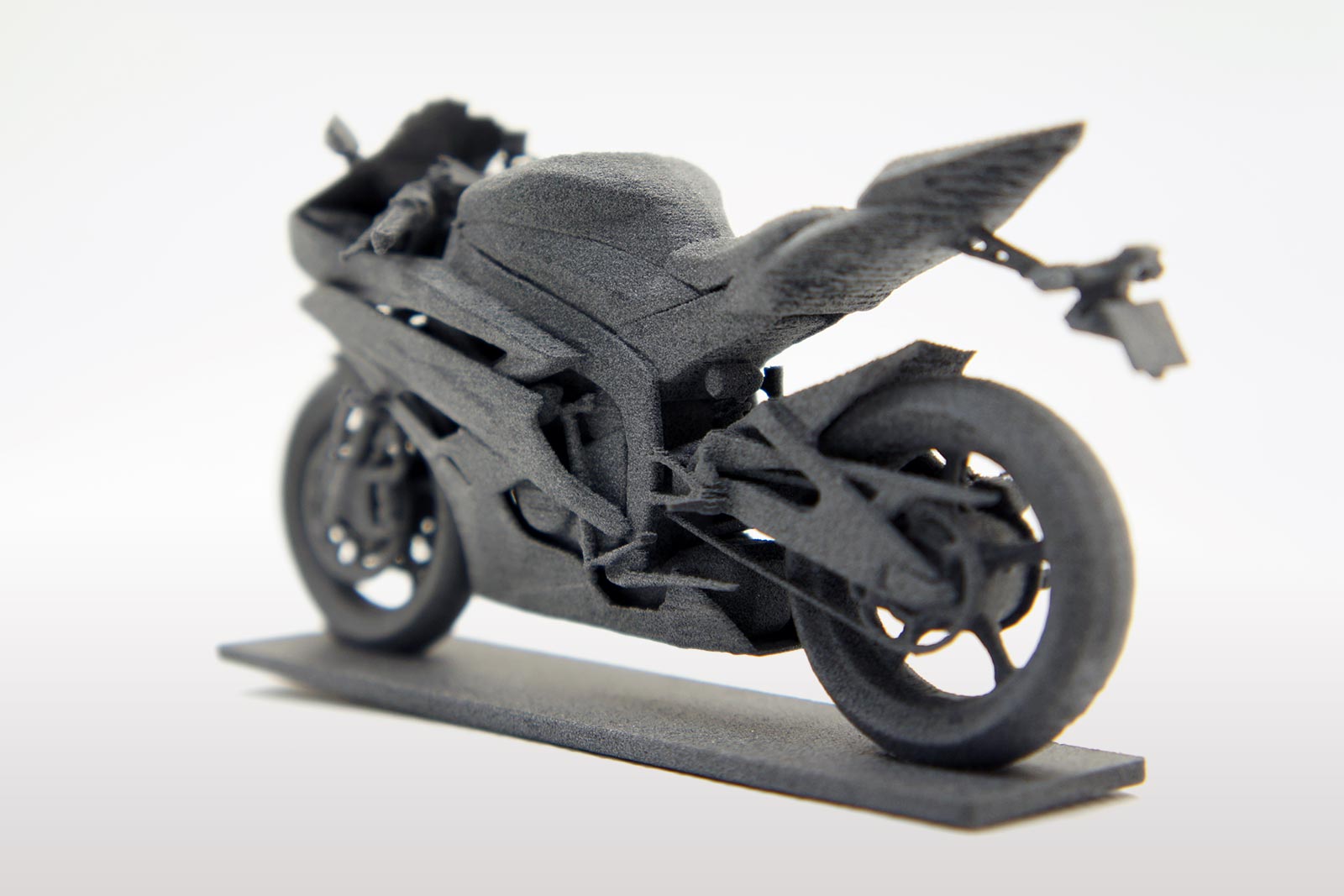

SLS 3D Printing, when it's detail and strength you need!

SLS 3D Printing (Selective Laser Sintering) offers yet another impressive and individual set of characteristics within the technology. SLS again works on the principle of depositing individual layers of consumable nylon powders, this time each layer is then fused by a passing laser, ultimately building layer upon layer until the final design object is achieved. The nature of SLS means that we are able to achieve very fine accuracy and detail including fully workable parts and because of the laser fusing effect on the nylon powder, extremely good strength properties are achieved to the point that in many cases a fully functional item can be achieved. As well the strong smooth nylon finishes, flexible TPU, which creates a tough but flexible working part can also be achieved. Another one of our in house technologies that we love using for the creation of technical working parts.

SiDe Design

SiDe Design