SiDe Design

Thermoforming plastics

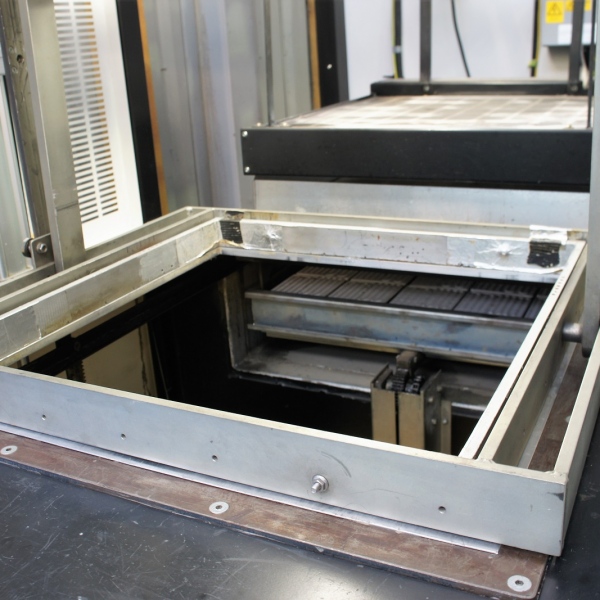

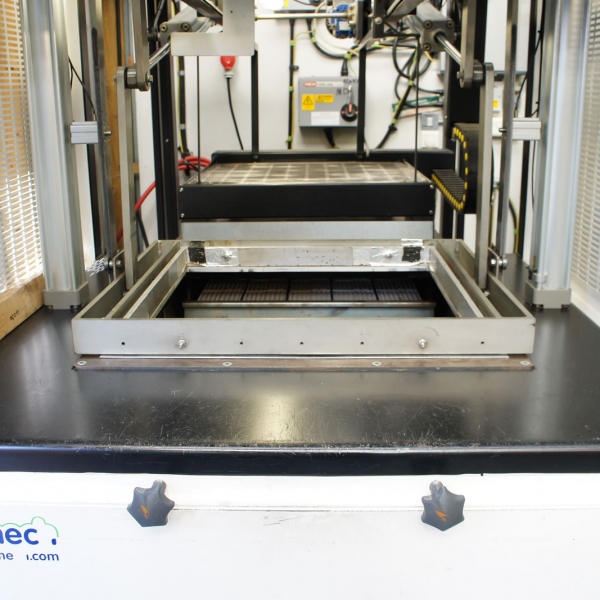

The vacuum forming process takes a sheet of thermoplastic material and creates a shell of the mould tool. It does this by heating the plastic sheet, pushing the mould tool(s) up into the soft heated material then, by vacuum, the material is drawn down around the tool design to make a strong, sharp detail forming. The item is then cooled to bring the plastic back to its original strength and the tooling withdrawn from the forming. Formings traditionally would then be trimmed out of the sheet material by hand or CNC to the final design.

SiDe Design

SiDe Design